MANUFACTURING

Jalax produces a wide range of metal parts. Thanks to in-house engineers who work closely with our clients, we guarantee cost-efficiency and the economical use of materials. Our high-tech machinery allows us to manufacture parts from both sheet metal and tube profiles, and weld them into complete components. Additionally, we can powder coat all products.

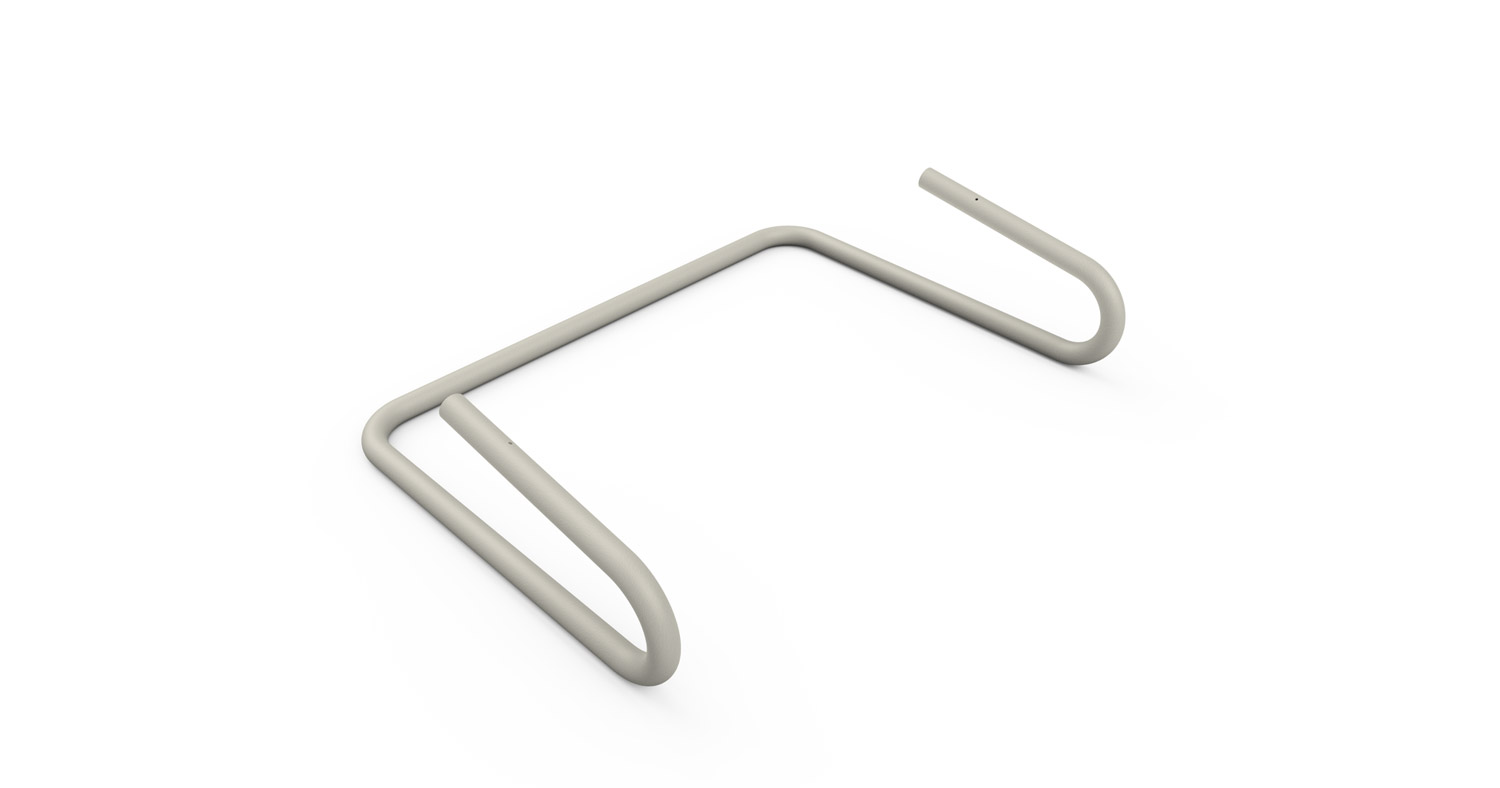

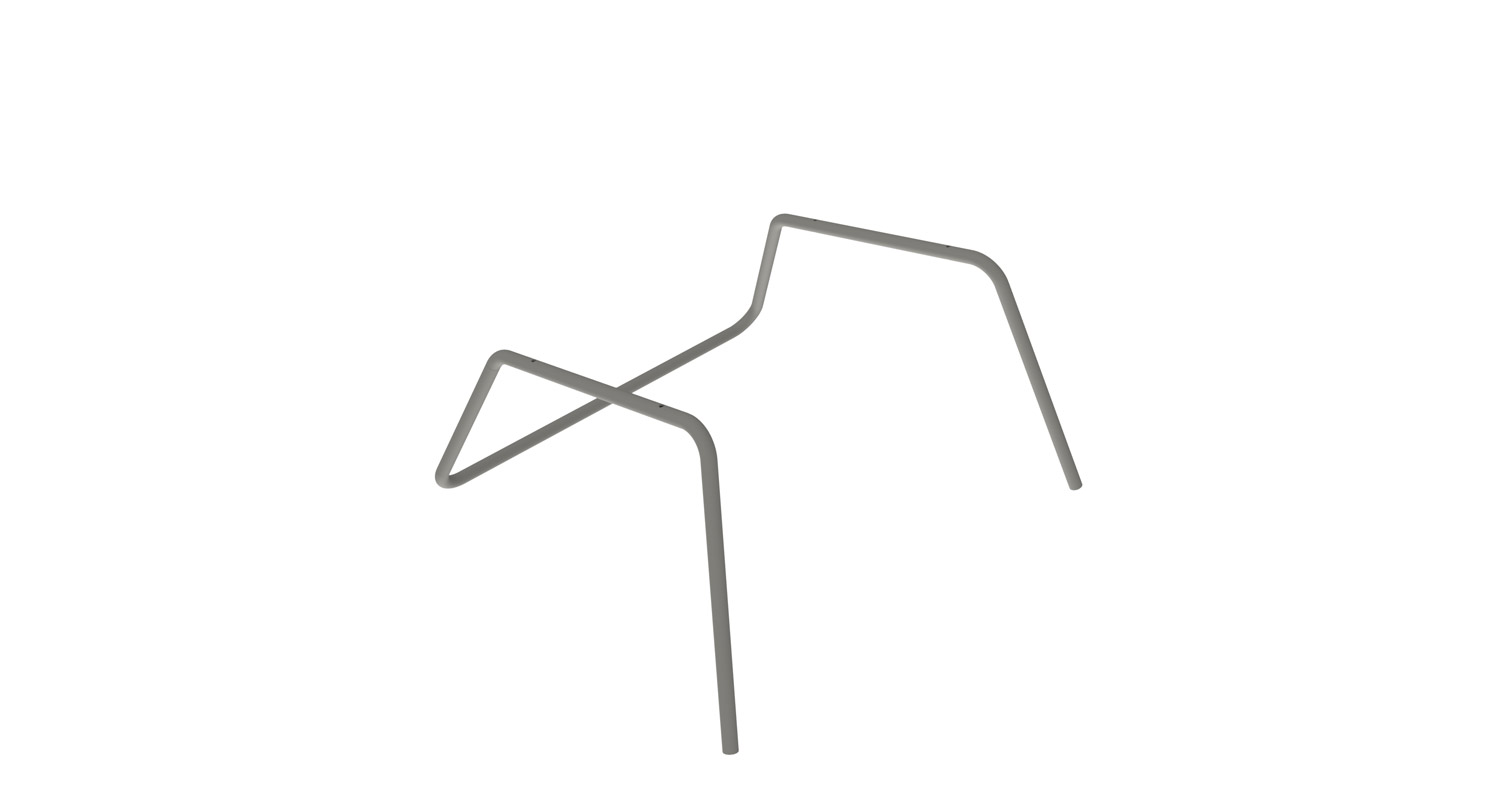

Tube Bending

AS Jalax has a long experience in tube bending. The new generation of tube bending equipment Grippa allows us to offer bending of even more complex details. We have the technical ability to bend round tubes and thicknesses up to d42x2.0mm suitable for the furniture industry. We also bend various square and oval profiles. The profile materials used are carbon steel and stainless metal. We have a significant selection of bending tools for the most common tube diameters and bending radii. In agreement with customers, we can always order more specific bending tools for less common tube sizes and radii.

Tube bending machine:

Tube bending machine Crippa 1042E

Max. tube diameter d: 42 mm x 2.0 mm

Tube max. length: 3300 mm

Max bending radius R: 150 mm

JALAX AS

Jalax AS, established in 1993, has grown over two decades from a small metal workshop into a modern high-tech facility that manufactures metal components for the world’s leading industrial companies. Our factory in Estonia employs 150 people and continues to expand.

QUALITY