MANUFACTURING

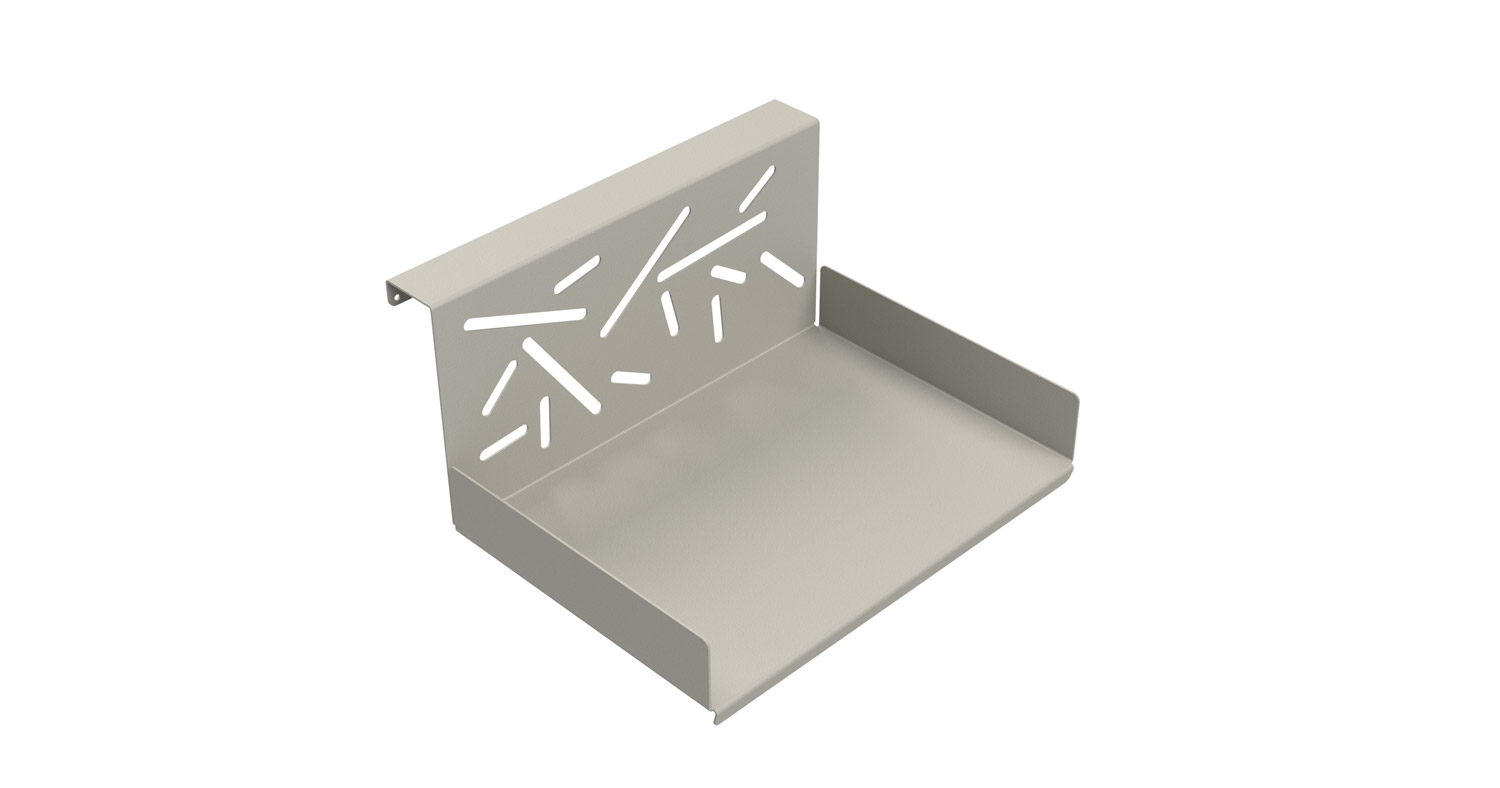

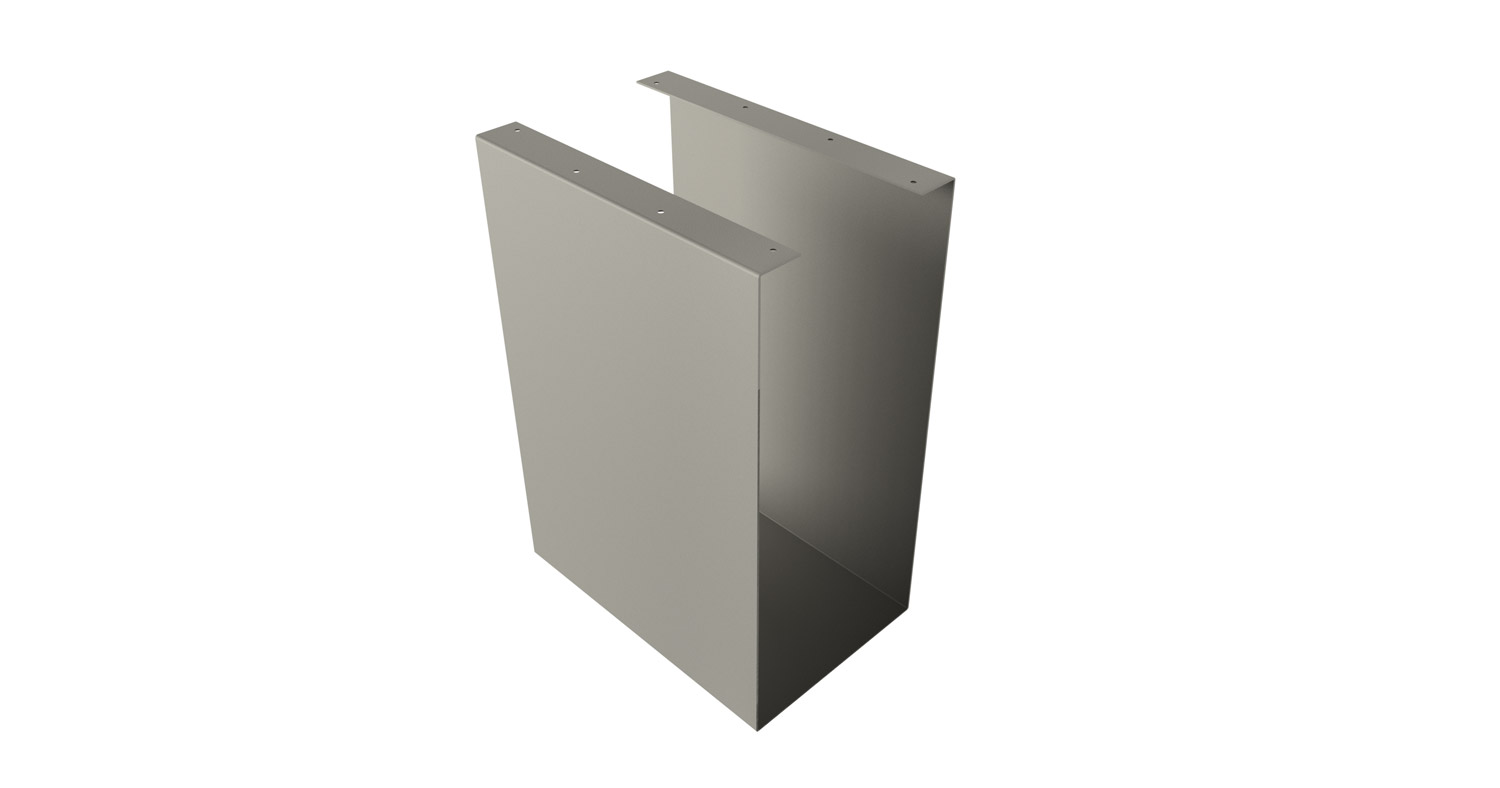

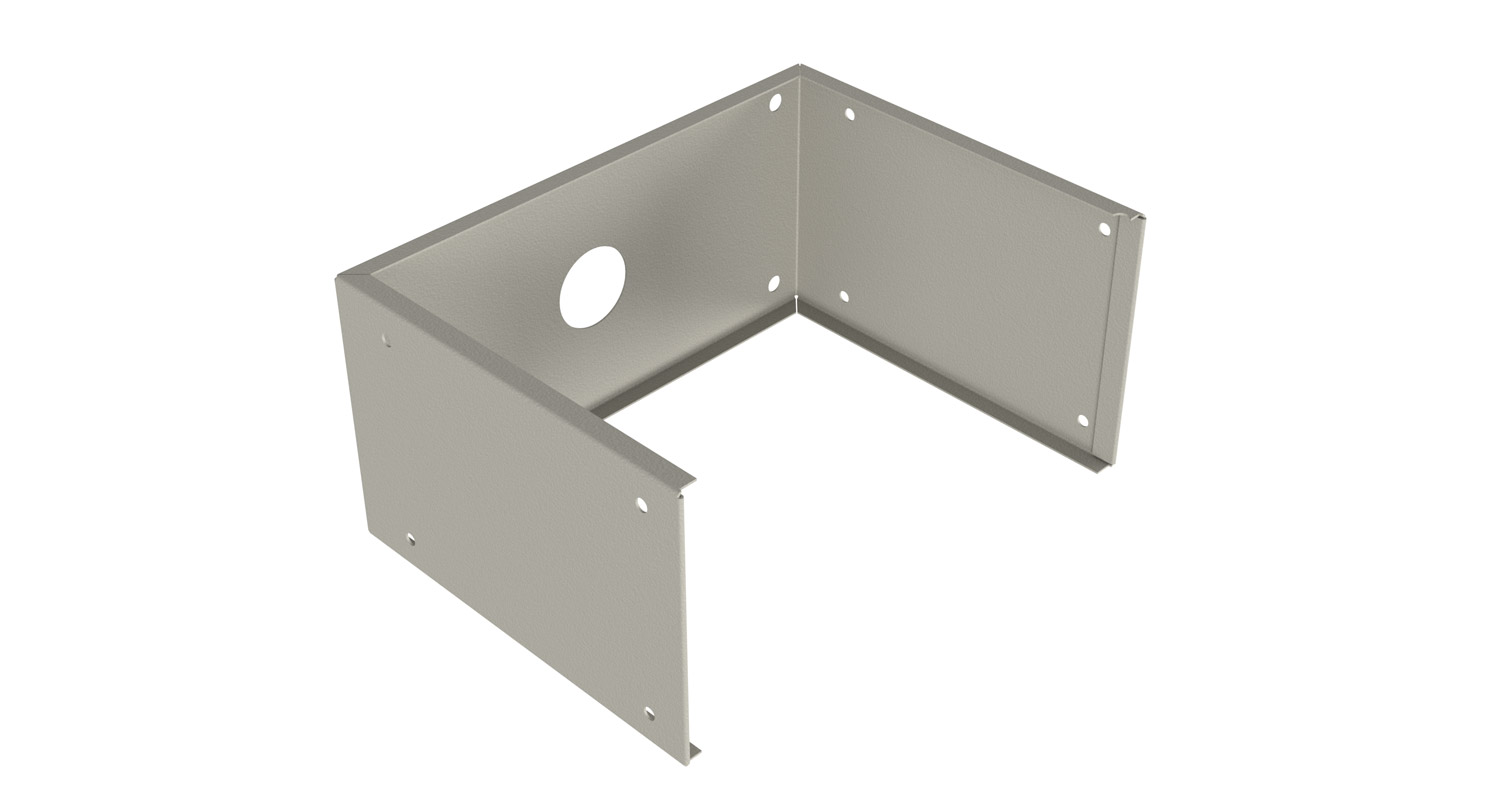

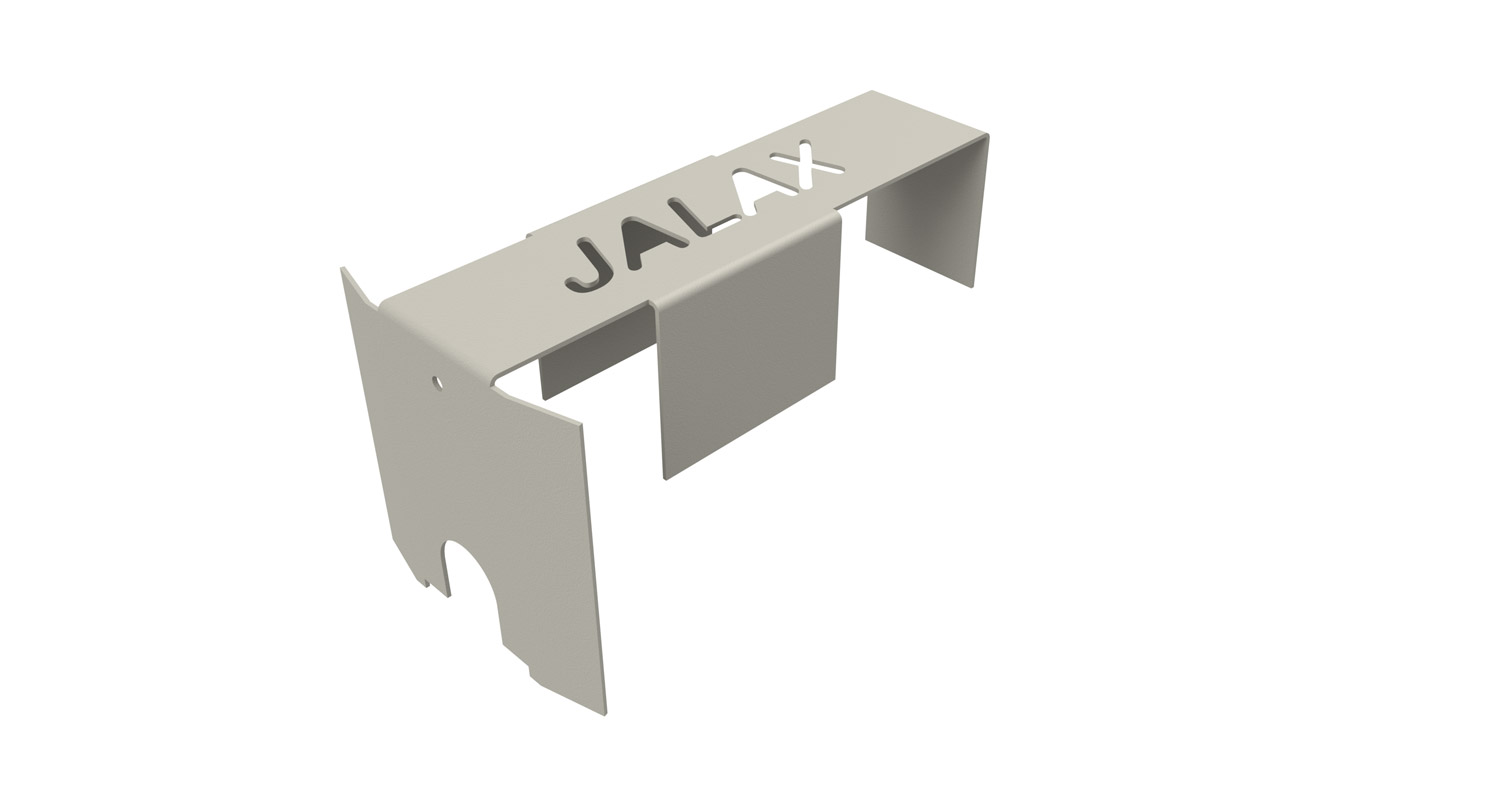

Jalax produces a wide range of metal parts. Thanks to in-house engineers who work closely with our clients, we guarantee cost-efficiency and the economical use of materials. Our high-tech machinery allows us to manufacture parts from both sheet metal and tube profiles, and weld them into complete components. Additionally, we can powder coat all products.

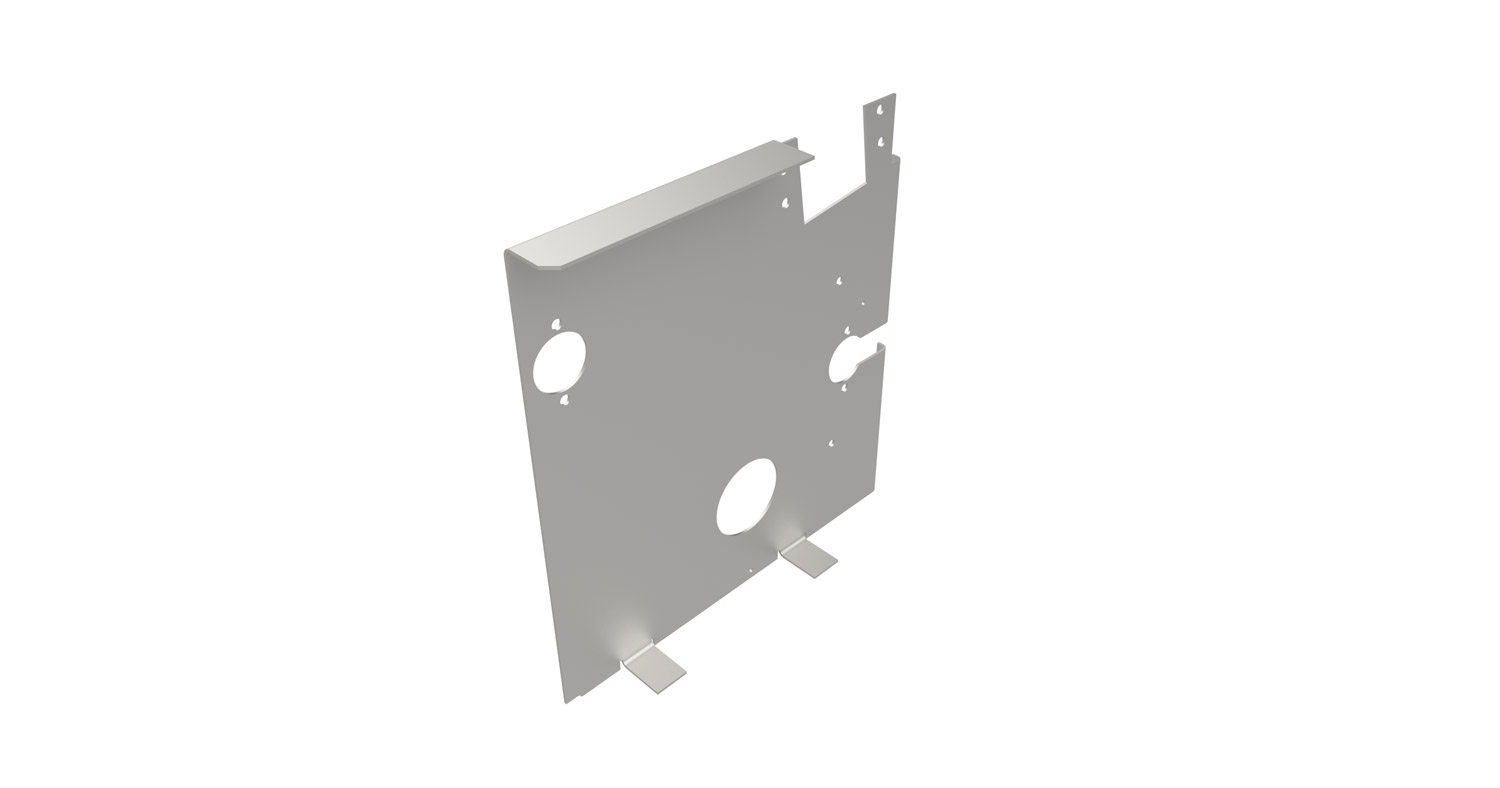

Sheet Metal Bending

AS Jalax has modern sheet metal bending equipment from Trumpf for bending sheet metal parts. In order to bend the parts, CNC programs are made on the device in advance, which ensures the accuracy and conformity of the bent parts. In addition, the devices use ACB laser angle control devices to detect and compensate for deflection deviations due to material properties.

We can roll bends with a larger radius on a CNC-controlled roller on a Biko machine.

Equipment used:

Trumf TruBend 5130

Maximum compression force: 130 t

Maximum length of the part: 3000 mm

Using laser angle control ACB and support device for bending larger parts

Trumpf TruBend 7050

Maximum compression force: 50 t

Maximum length of the part: 1500 mm

Using laser angle control ACB

Trumpf Trumabend V85 S

Maximum compression force: 85 t

Maximum length of the part: 2500 mm

Rull valts Biko B4-2014 CNC

Number of rolls: 3

Roller diameter: 145/130/130 mm

JALAX AS

Jalax AS, established in 1993, has grown over two decades from a small metal workshop into a modern high-tech facility that manufactures metal components for the world’s leading industrial companies. Our factory in Estonia employs 150 people and continues to expand.

QUALITY