MANUFACTURING

Jalax produces a wide range of metal parts. Thanks to in-house engineers who work closely with our clients, we guarantee cost-efficiency and the economical use of materials. Our high-tech machinery allows us to manufacture parts from both sheet metal and tube profiles, and weld them into complete components. Additionally, we can powder coat all products.

METAL FABRICATION

Jalax AS technology includes cutting, bending and other processing of both tube and sheet material. Our equipment allows us to perform a wide variety of metal processing processes on site at the factory, without the need for multiple subcontractors for different jobs, allowing us to offer a competitive end-to-end product price. We use modern Trumpf laser cutting and bending machines and software that ensure efficient production and resource savings.

See more under our detail production services:

- Laser cutting of tube

- Bending of tube

- Laser cutting of sheet metal

- Bending of sheet metal

- Milling and turning

Stamping

As an additional option, we can also offer our customers some stamping of details. We have several eccentric presses with an impact force of 6-160 tons.

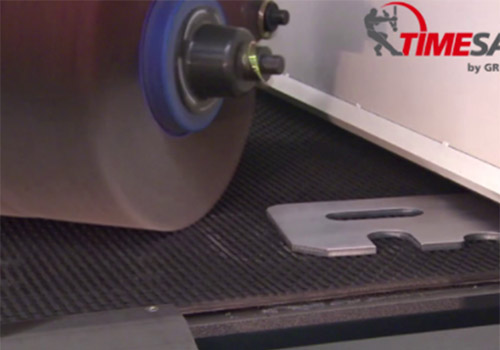

Cleaning of details

There are various options for cleaning details in Jalax to give the cut details a sufficient edge radius and surface smoothness. The edges of the cleaned part are safe for the user and also ensure high-quality painting results.

| The plane of the sheet metal parts grinder TimeSaver  |

Smaller details vibratory finishing device from Rösler  |

JALAX AS

Jalax AS, established in 1993, has grown over two decades from a small metal workshop into a modern high-tech facility that manufactures metal components for the world’s leading industrial companies. Our factory in Estonia employs 150 people and continues to expand.

QUALITY