HISTORY

In this page we would like to give you a short overview of our investments.

During 2018-2019, Jalax invested more than 3,3 million euros in various equipment. Investments were made in improving and renewing laser and bending technology.

2020 – A YEAR OF CHALLENGES

2020 was a very special year. Like most businesses, Jalax lost its business volume due to Covid. The company turnover fell 25% but despite of the challenges, we were able to keep 99% of supply security.

Despite of significant in business volumes, Jalax managed to keep 99% due date performance throughout the year. 99% due date performance continues to be the cornerstone of our Reliable Response offer to all our make-to-order clients. This year we are even more confident that Jalax can offer exceptionally good due date performance as new machinery increases both reliability and quality.

We strive for ongoing improvement, where things, decisions and information move quickly. Trust is the basis in this partnership and we keep our word.

THE NEW ERA OF TUBE PROCESSING IN JALAX

MORE POWER AND PRECISION IN TUBE CUTTING

According to machine producer Trumpf, the new model TruLaser Tube 5000 Fiber 3kw

installed on Jalax in May 2019 is the fastest tube cutting machine in the world. To our clients this means short processing times for a large range of possible tubes and profiles. Other improved capabilities are:

![]() ability to cut also tubes from stainless steel, aluminium, copper and bronze;

ability to cut also tubes from stainless steel, aluminium, copper and bronze;

![]() ability to cut tubes up to length 4,5 meters, up to diameter 152 mm and up to wall thickness 8 mm;

ability to cut tubes up to length 4,5 meters, up to diameter 152 mm and up to wall thickness 8 mm;

![]() the bevel cutting option that enables high-quality bevel cuts of up to 45°

the bevel cutting option that enables high-quality bevel cuts of up to 45°

![]() accuracy of cutting parallel holes and cuts

accuracy of cutting parallel holes and cuts

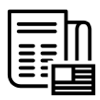

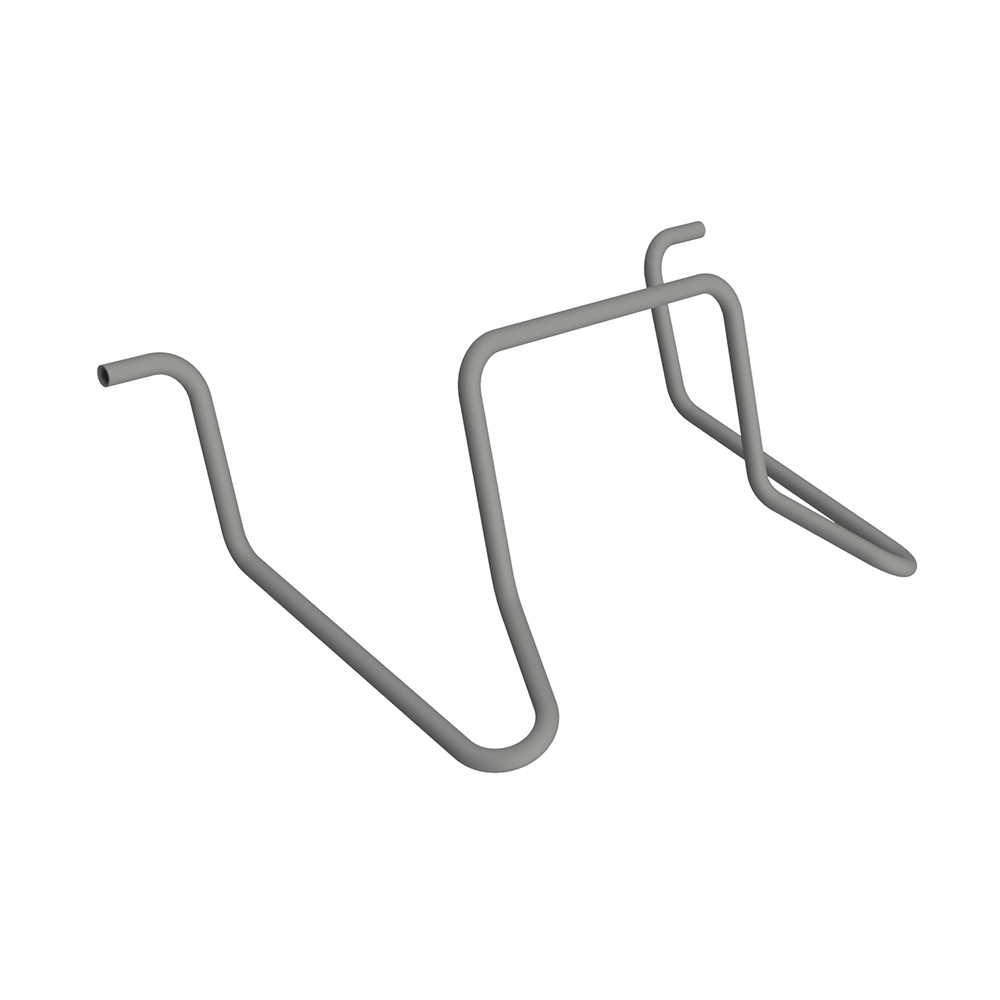

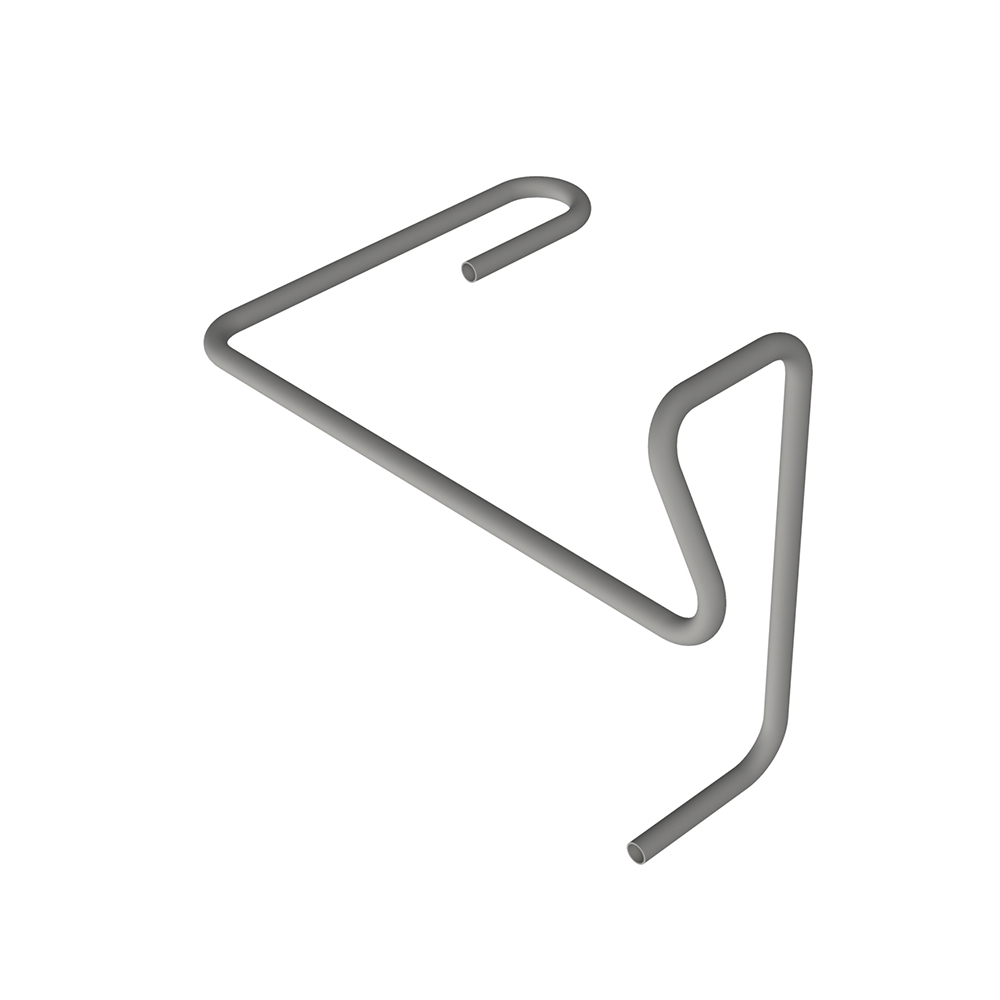

STATE-OF-ART TUBE BENDING

In February 2019 Jalax installed a new CNC tube bending machine Crippa 1042E. The new machine belongs to Crippa Up&Down series that offers right and left bend directions for limitless bends. The new machine opens new opportunities – Jalax can offer much larger variety of bended tube components than ever before.

Main benefits are:

![]() A cross movement of the bending head makes possible tube geometries during single operation that usually require post processing operations.

A cross movement of the bending head makes possible tube geometries during single operation that usually require post processing operations.

![]() Bending of square, round tubes regardless of profile with diameter from 6 mm up to 42 mm.

Bending of square, round tubes regardless of profile with diameter from 6 mm up to 42 mm.

![]() Electro Servo control feature increases bending accuracy and allows us producing small batches without scrap and with consistent quality.

Electro Servo control feature increases bending accuracy and allows us producing small batches without scrap and with consistent quality.

![]() A high vertical excursion makes it possible to simultaneously use multiple tools with different radius and clamping.

A high vertical excursion makes it possible to simultaneously use multiple tools with different radius and clamping.

COMBINED BENEFITS

The combined result of Jalax tube processing investments is two-fold: Tube cutting process was Jalax’s production bottleneck before the investment. After the investments Jalax has significantly more tube processing capacity and we are now open for new orders and challenges. At the same time higher precision tube cutting and vastly increased tube bending possibilities will open new markets for multi-directional bended tube components. We hope that also our existing clients will find ways to use these possibilities in their new exciting products!

JALAX AS

Jalax AS, established in 1993, has grown over two decades from a small metal workshop into a modern high-tech facility that manufactures metal components for the world’s leading industrial companies. Our factory in Estonia employs 150 people and continues to expand.

QUALITY