MANUFACTURING

Jalax produces a wide range of metal parts. Thanks to in-house engineers who work closely with our clients, we guarantee cost-efficiency and the economical use of materials. Our high-tech machinery allows us to manufacture parts from both sheet metal and tube profiles, and weld them into complete components. Additionally, we can powder coat all products.

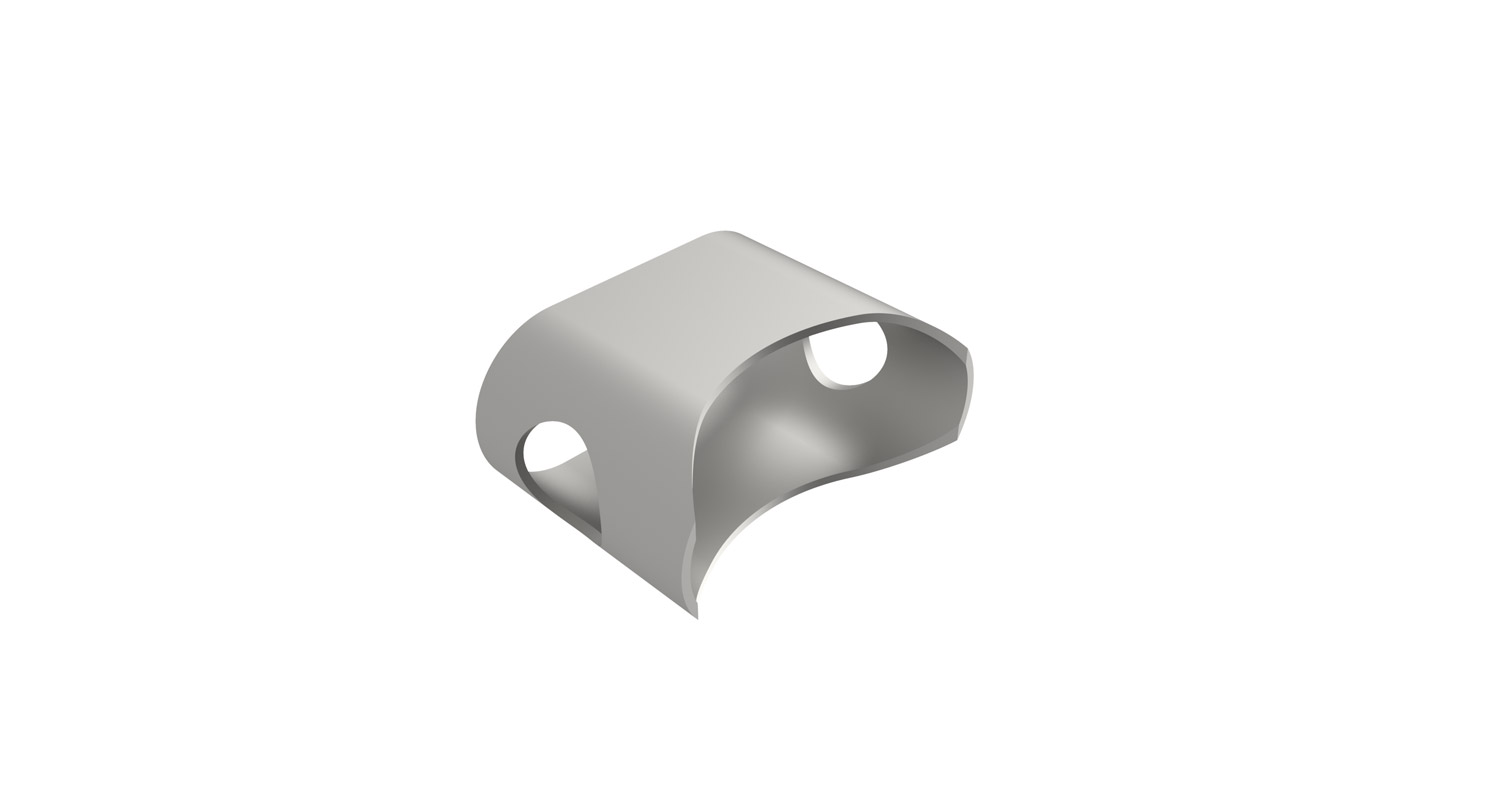

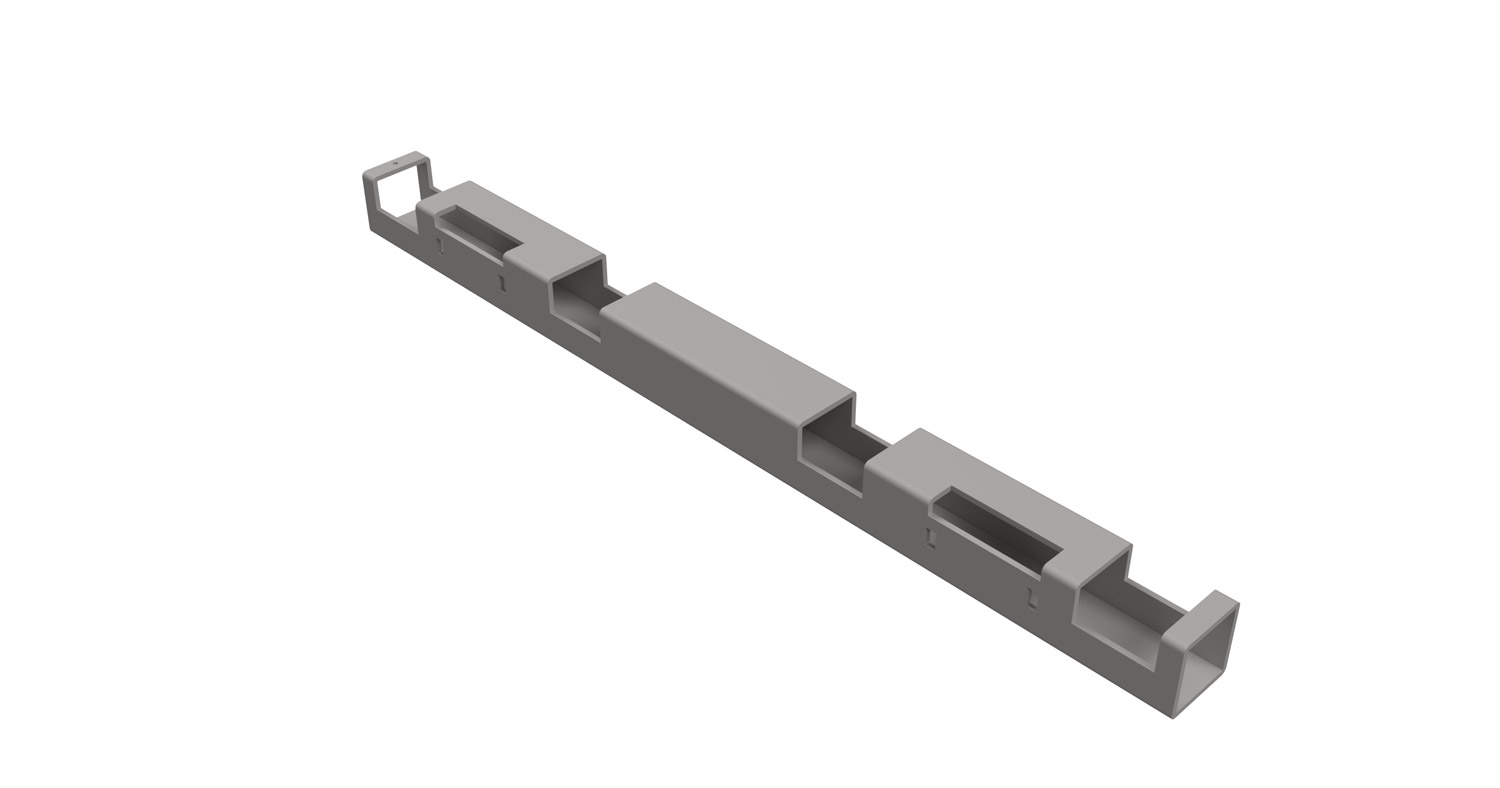

Laser Cutting of Tubes

To cut tube profiles, we use modern tube laser cutting equipment from the well-known company Trumpf. Tubular lasers also allow you to cut very complex shapes and openings in round, square and oval tubes. The material of the profiles used can be carbon steel, stainless steel and aluminum. Tubular lasers offer greater efficiency and flexibility than a combination of band sawing and drilling with conventional machining methods.

The brands and most important parameters of our tube lasers are:

TruLaser Tube 5000 Fiber 3kw

aser power: 3000W

max length of the part to be cut: 6000 mm

Cutable round tube max. diameter: 152 mm

Cut square tube max. diagonal: 152 mm

max. material thickness: 8 mm

Torulaser Tubematic TLF 2400

laser power: 2400 W

max cut length of workpiece: 3000 mm

Max. Diameter of the round tube to be cut: 150 mm

Cut square tube max. diagonal: 150 mm

Max. material thickness: 4 mm

JALAX AS

Jalax AS, established in 1993, has grown over two decades from a small metal workshop into a modern high-tech facility that manufactures metal components for the world’s leading industrial companies. Our factory in Estonia employs 150 people and continues to expand.

QUALITY